Caldic Special Pulleys

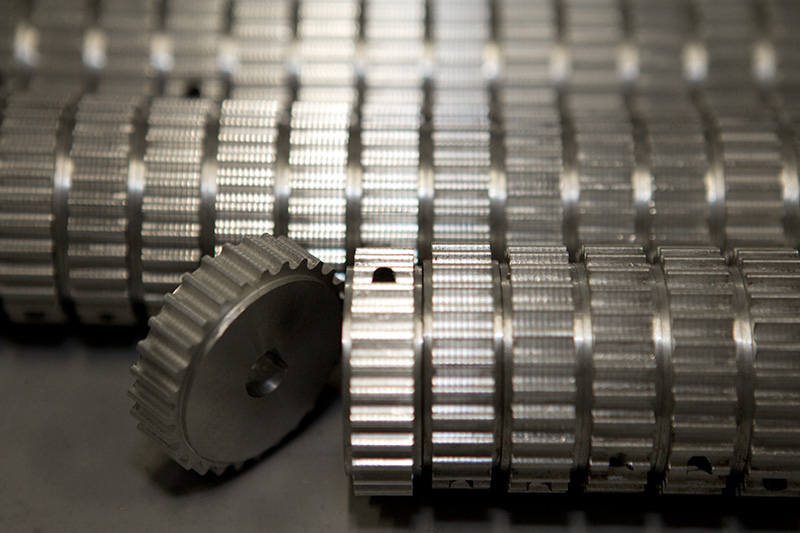

Caldic Techniek has its own CNC production facility in Rotterdam. With several CNC lathes and two Pfauter milling machines we produce here from aluminum, steel and stainless steel rod material a wide assortment of timing belt pulleys. With our capacity to produce a wide range of products and our more than 25 years of experience, we can rightly call ourselves a specialist in the field of pulley production.

Timing belt pulleys made according to your design

With your drawings and our expertise, together we will develop the best possible pulley for your application. We have very extensive manufacturing and machining capabilities that allow us to produce pulleys that meet a wide range of specifications and requirements.

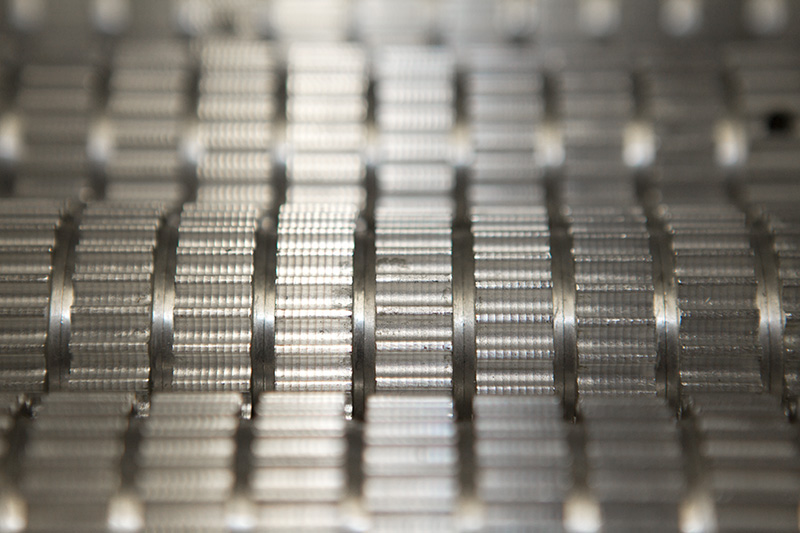

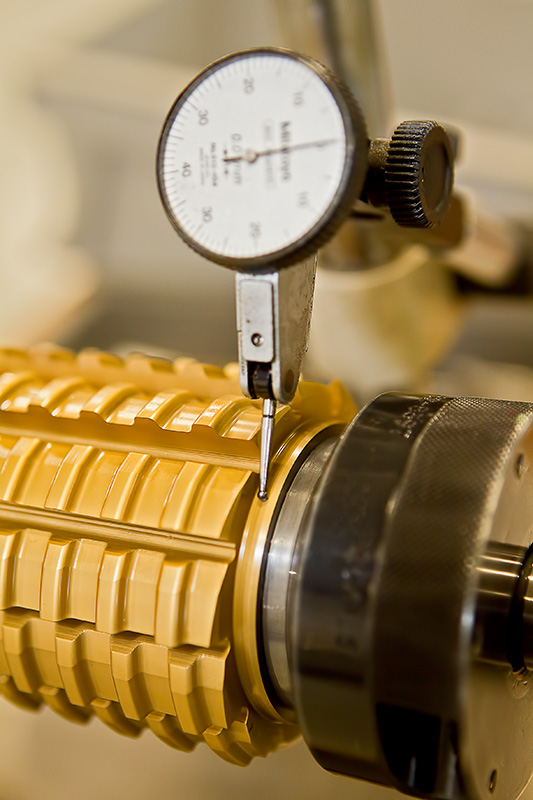

Tooth profiles with the highest accuracy

We chose the process of unwinding milling. With our Pfauter machines, this allows us to unwind the gears of the pulleys instead of inserting gears. This allows us to realize tooth profiles with the utmost accuracy. We can make the T / AT and the HTD gears in various pitch sizes, as well as Polychain, MR and the classic gears from MXL and XL to XXH. For positioning applications, we can also produce T / AT gears in backlash-free “0” design.We chose the process of unwinding milling. With our Pfauter machines, this allows us to unwind the gears of the pulleys instead of inserting gears. This allows us to realize tooth profiles with the utmost accuracy.

Wide range of type gears

Not only do we have high-precision Swiss gearing machines, but we have also built up a very extensive range of unwinding cutters over the years, allowing us to make a wide arsenal of timing belt pulleys.

Type of unwinding cutters

- MXL – XL – L – H – XH

- HTD3 – HTD5 – HTD8 – HTD14

- T2,5 – T5 – T10 (in normal and zero clearance)

- AT3 – AT5 – AT10 (in normal and zero clearance)

- AT20

- GT-5MR & 8MR

- S2M

- GT – Polychain 8M

- Powergrip GT 3M

Inquire about available tooth numbers with one of our specialists

Pulleys with surface treatment

If you want to provide your pulleys with a form of surface treatment to make them suitable for application in specific processes you have also come to the right place at Caldic Techniek. We can anodize, chemical nickel plating, blacken or phosphate the pulleys.

Possible surface treatments to be performed

Through a network of partners, we can offer a wide variety of surface treatments such as

- Normal bright anodizing

- Normal color anodizing

- Hard anodizing

- Chemical nickel plating

- Chemical blackening

- Phosphating

Choice of material

We have chosen to standardize our materials as much as possible. This enables us to keep an efficient stock. Of course an alternative material is available on request at extra cost. Ask one of our specialists about this.

We have chosen both steel and aluminum as standard for high quality. For aluminum, we apply grade 6026 or equivalent automobile grade. For steel, we apply C45 or 11SMn9. The already mentioned surface treatments are optimally guaranteed with these materials.

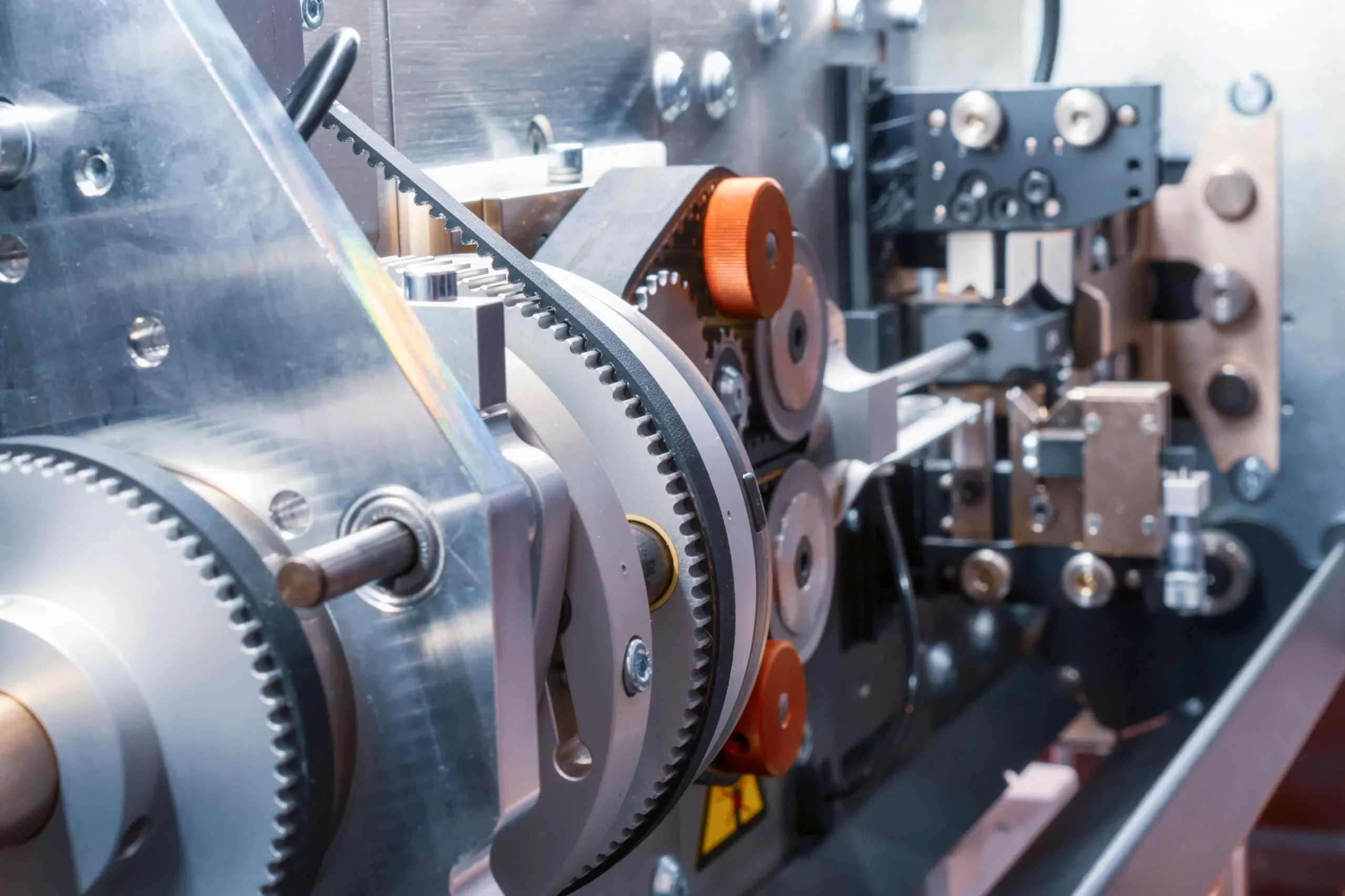

High quality assembly of flange rings

Over the years we at Caldic Techniek have gained a lot of knowledge and experience about mounting flange rings on pulleys. As a result we have developed a special machine capable of mounting the flange ring very efficiently and with consistent quality on the pulley. This allows the flanges to absorb large lateral forces of the belt without being pushed off the pulley. This prevents pulleys with loosening rings that lead irrevocably to belt damage and production downtime.

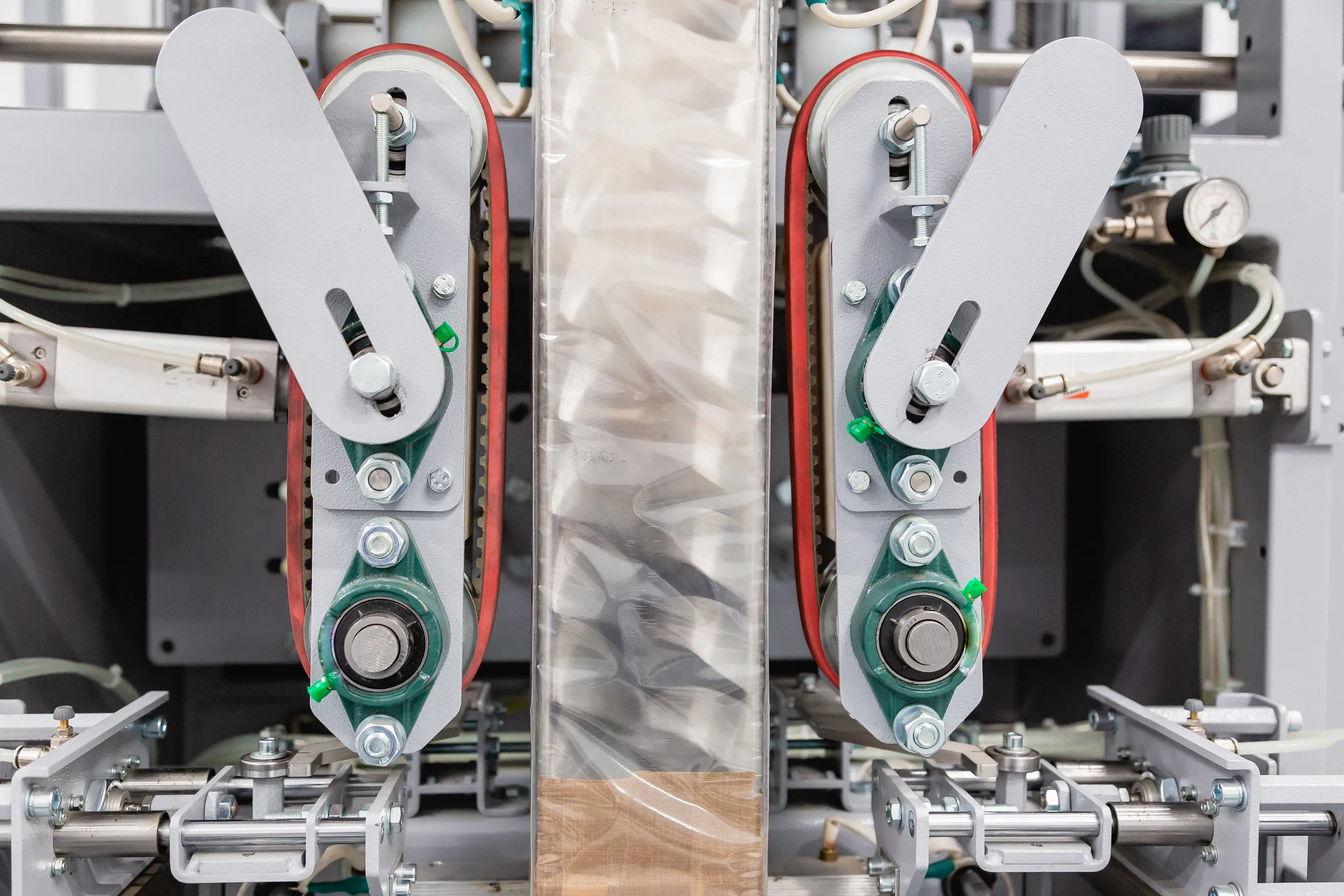

Production of Easy Drive pulleys

We are licensed to produce Easy Drive pulleys in our workshop. The Easy Drive technology ensures optimal belt control in a simple and effective way. This ensures smooth, quiet and stable running between the timing belt and pulley.

Read more about Easy Drive pulleys here

The complete solution with Caldic Engineering

Due to our extensive experience in producing pulleys and our broad knowledge of timing belts Caldic Techniek is the partner of choice to support you in designing your complete application. By advising you on the whole issue we can deliver a pulley that is easy to mount in your setup, that perfectly matches the timing belt and that is also cost optimized.

We are happy to work along with you

Finding the right timing belt transmission starts with understanding your issue. After all, there is an optimal configuration of timing belt and pulley for every application. By better understanding the intended purpose of the timing belt transmission, we can find the optimal solution for your issue, within our endless range of timing belts and pulleys equipped with all possible machining.

Our experienced experts are ready to think with you.

Looking for technical support from our specialist?

Suppliers & Brands

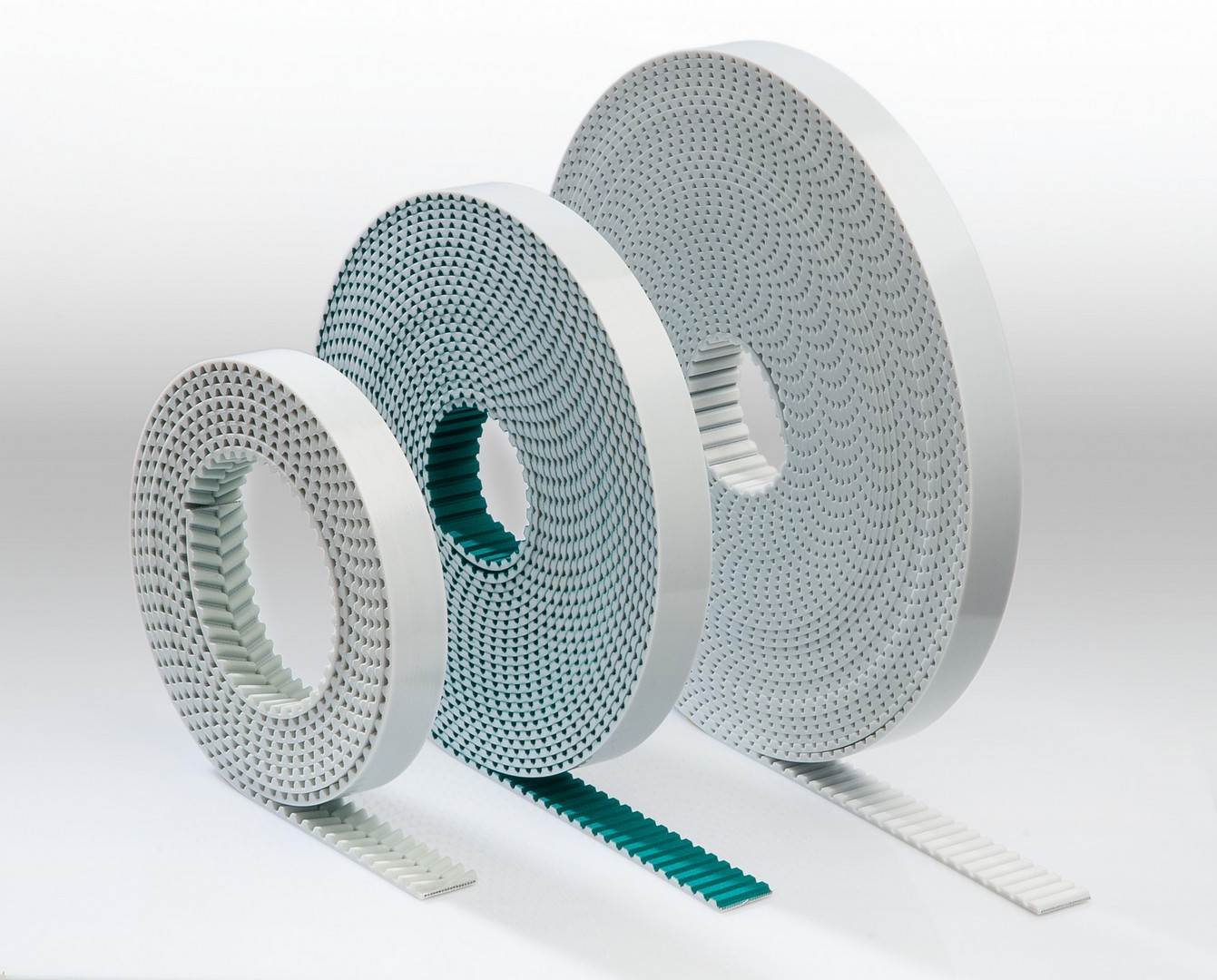

Related Products

Mechanical power transmission

Positioning

Conveying by timing belt

Vacuum belts

Special Timing Belt

easy drive Pulleys