Mechanical power transmission

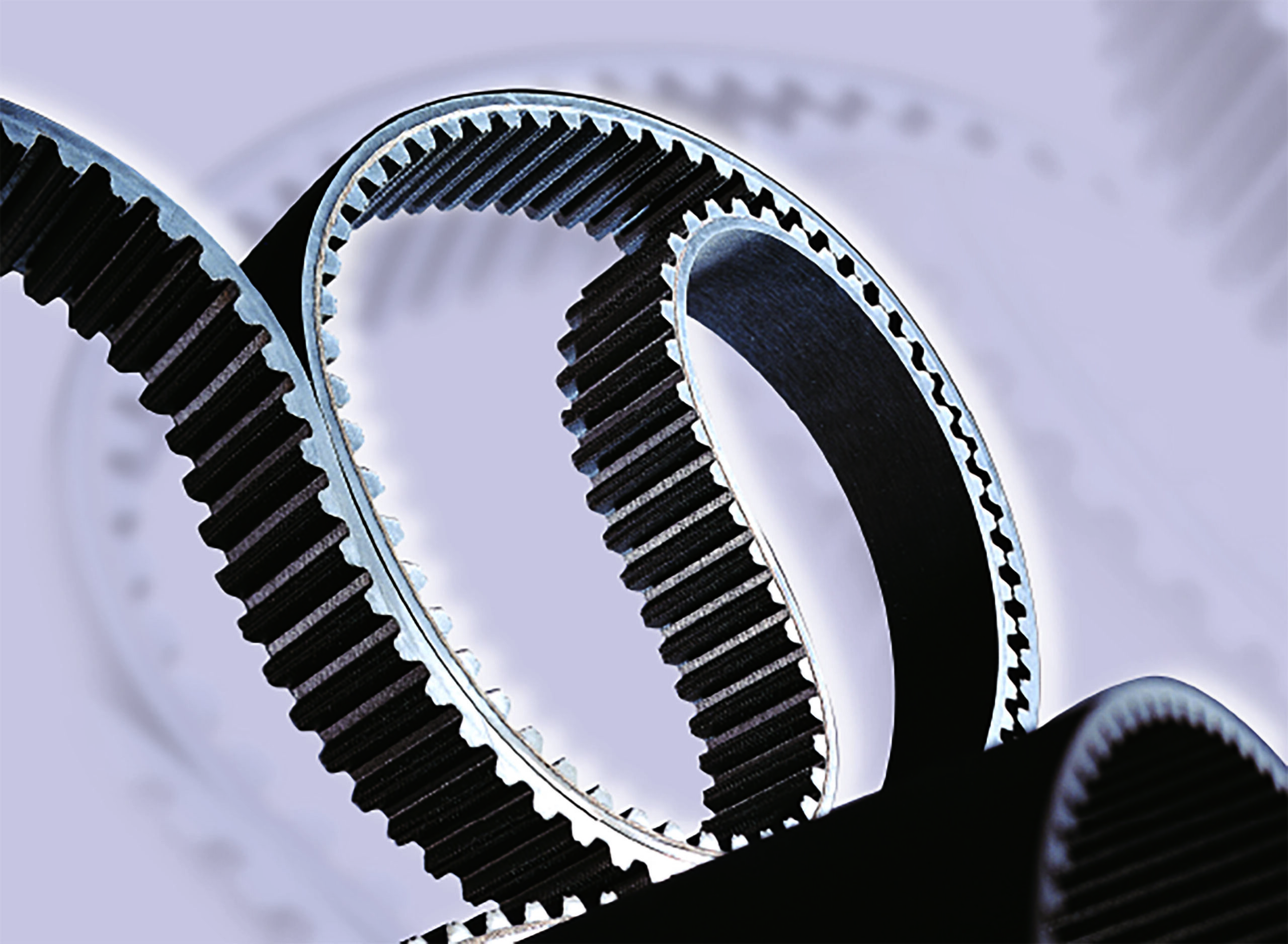

Because of their strength and accuracy, timing belts can be used to transmit power for various applications. For different forms of power transmission, timing belts are available with specific characteristics. With high powers we can achieve high speeds as well as drive heavy systems.

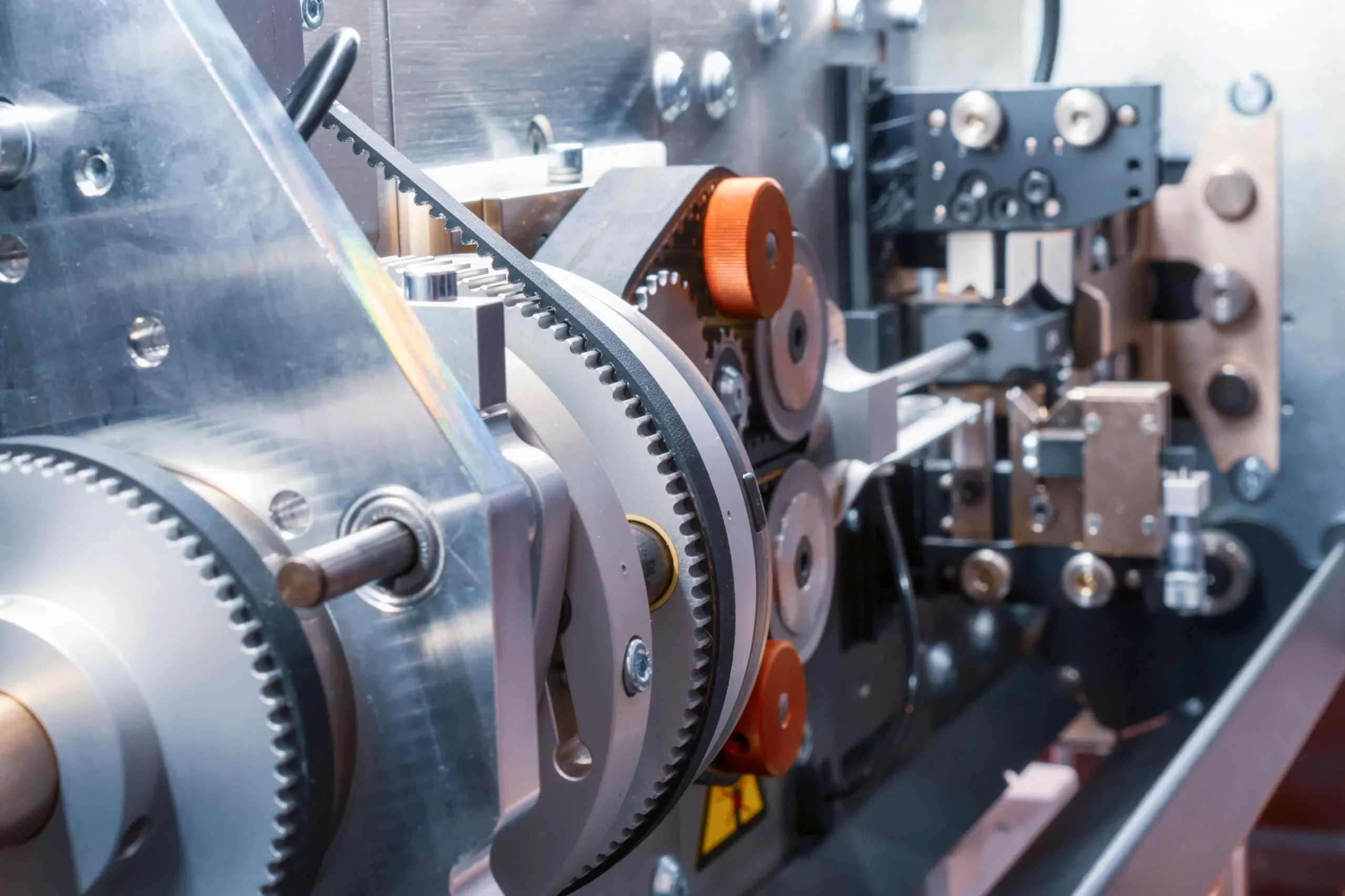

Timing belt drives for mechanical power transmission

By applying new materials for tensile cords and by working with reinforced rubber compounds, new high-power timing belts are constantly being developed. With these high power toothed belt transmissions, you are able to transmit greater power ever more compactly and with higher reliability.

The right timing belt

When transmitting high forces through a timing belt in a dynamic application, tooth jump needs to be avoided to increase life of your drive. We will be happy to provide you with specialized advice on the application of the correct tooth profile for your specific application.

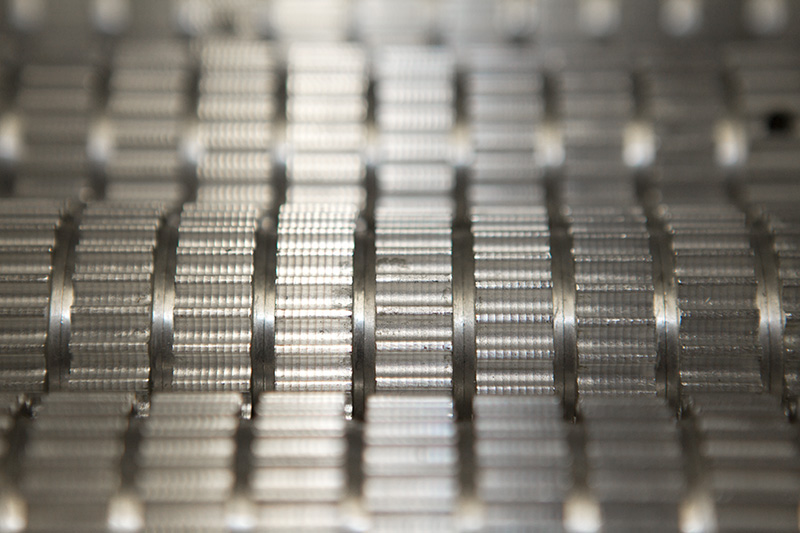

Toothing

Selecting the right toothing for a timing belt transmission depends on your drive. For higher dynamics, the parabolic tooth shape RPP or HTD is an appropriate choice, but there may be more important selection criteria, such as environmental variables. We are happy to help you with advice on the application of the right gearing for your transmission.

-

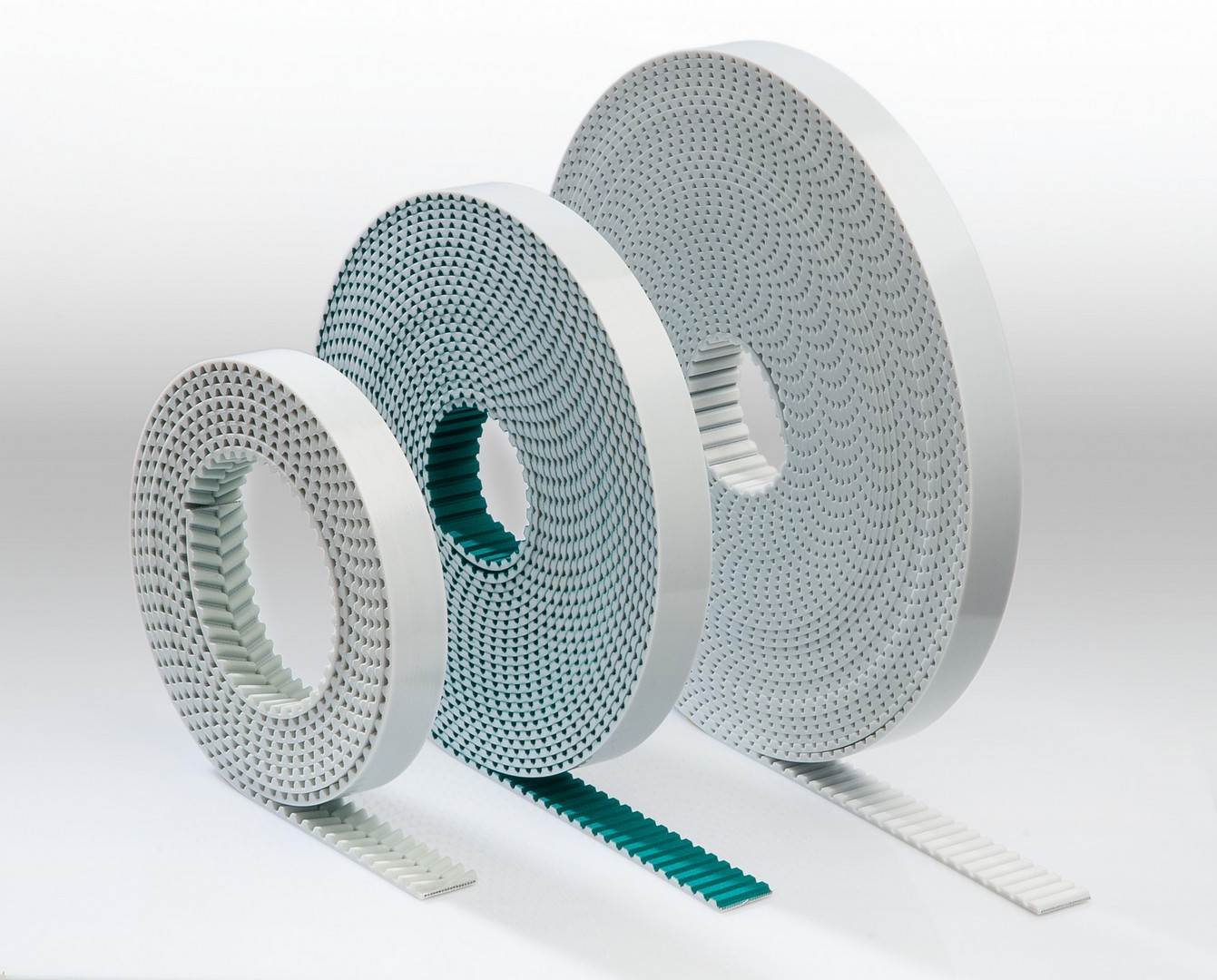

Rubber endless spooled timing belt HTD/RPP and high power

For good mechanical power transmission, neoprene endless spooled timing belts are the ideal solution. The tooth shape is ideally suited for transmitting large torques and can run at high speeds. The Megadyne RPP belts are interchangeable 1:1 with the HTD profiles. In addition, Megadyne has a variety of high power belts such as the Silver, Gold, Platinum and Titanium.

Tooth type

RPP, RPP Silver, RPP Gold, RPP Platinum and RPP Titanium Cords Glassfiber and hybrid cords Material Neoprene (possibly reinforced) -

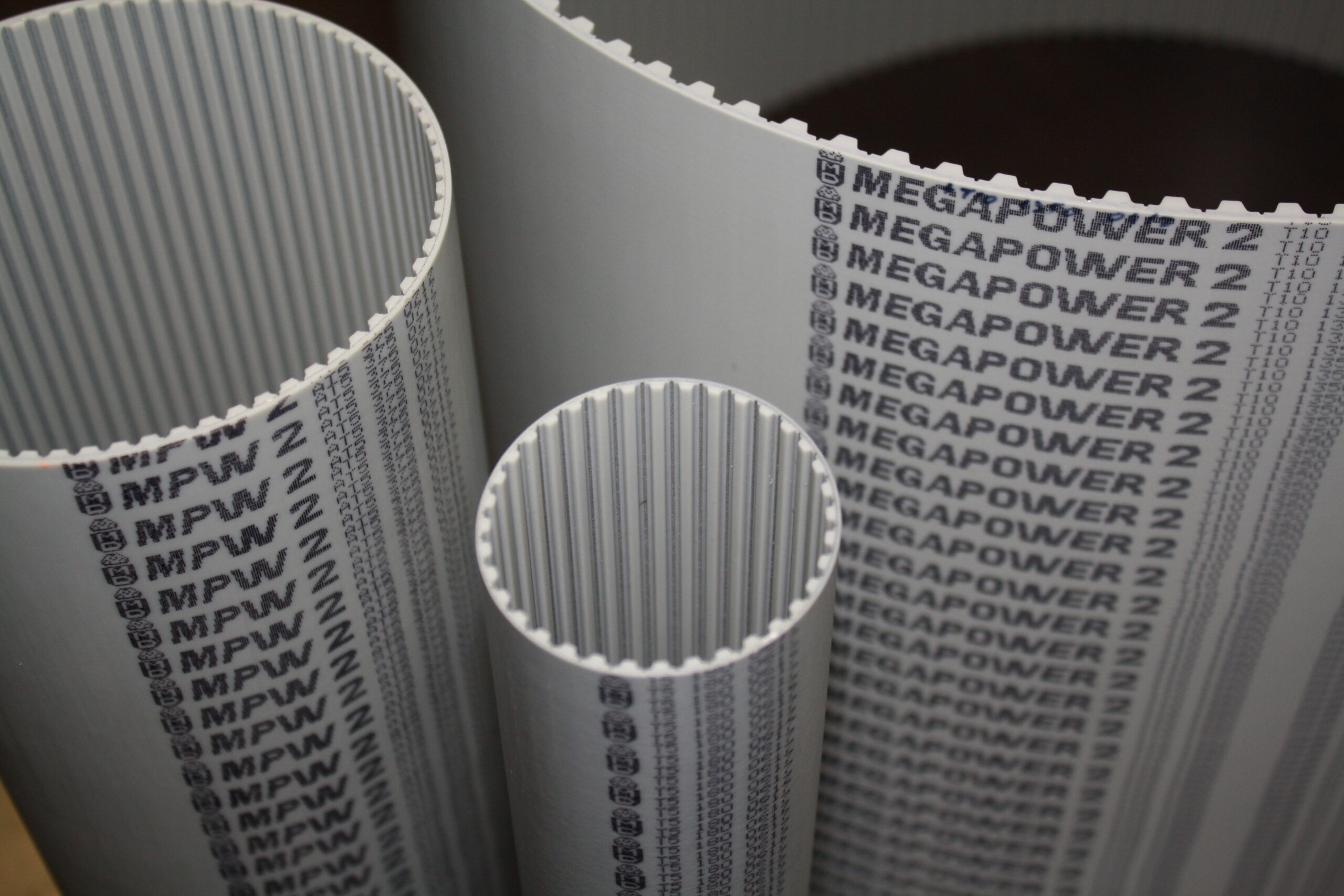

PU endless spooled belts, short lengths

If polyurethane timing belts are preferred because of weight (aluminum pulleys) or environmental variables, the endless spooled belts from Megadyne (Megapower) or Elatech (iSync) are the solution.

Tooth type

T2,5 – T5 – T10, AT5 – AT10 and some classical forms Drawstrings Steel, High Power, High Flexibility, HPF, Kevlar, RVS Material Thermoset PU -

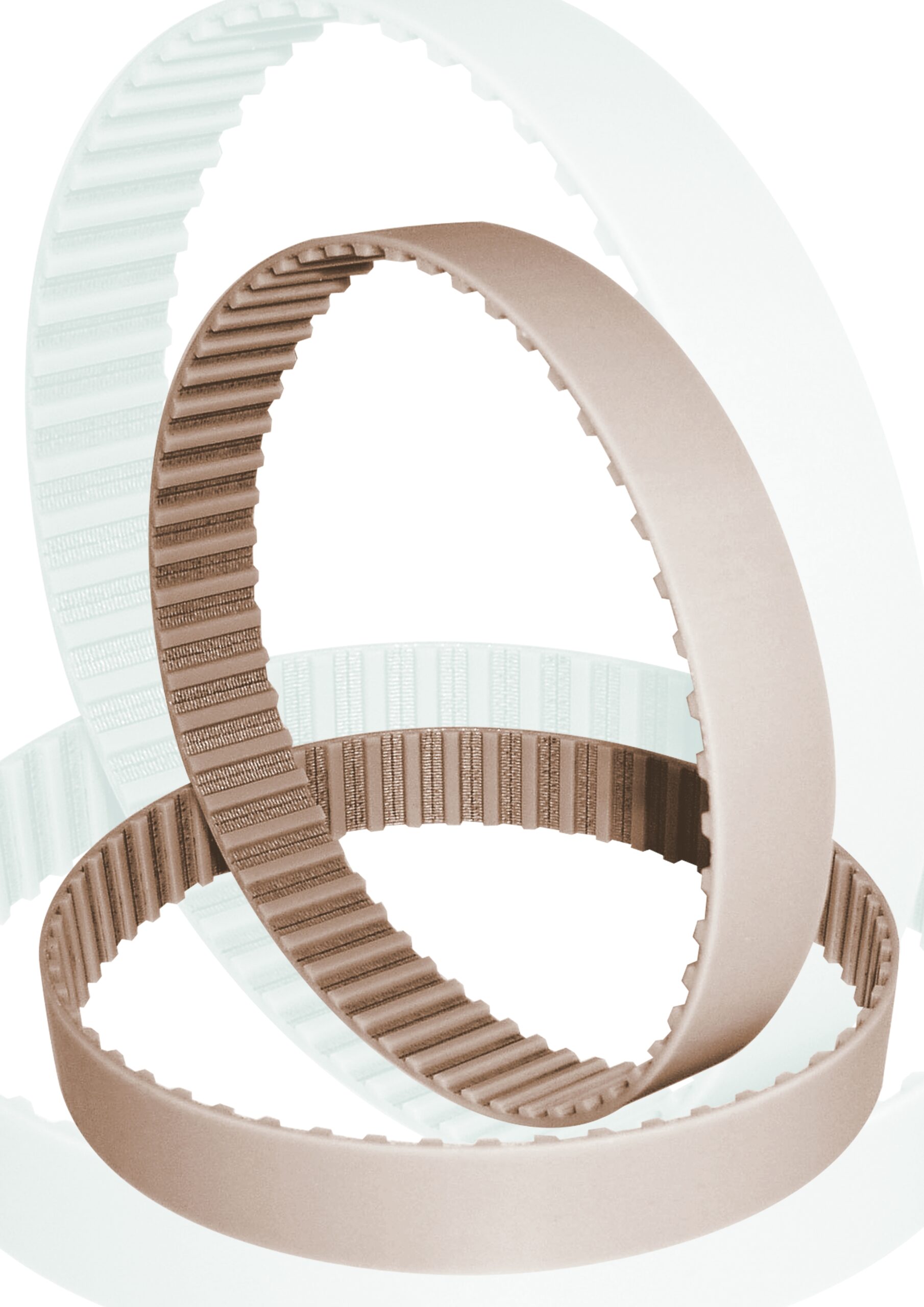

PU endless spooled belts long lengths

If the standard lengths of PU endless spooled belts are not enough and a welded belt is too weak, then the endless spooled timing belts from Megadyne (MegaFlex) or Elatech (Ela-Flex) are the right solution. In almost all types of tooth, these belts can be made to the desired length up to a length of over 20 meters. The endless spooled tensile cords.

Because these belts are made from a Thermoplast PU, the belts can easily be provided afterwards with a covering on the back or tooth side and/or lugs.

Tooth type

T, AT, HTD, RPP, Eagle, ATG, and some classical forms Cords Steel, High Power, High Flexibility, HPF, Kevlar, RVS Material Thermoplast PU Cams Optional Coating tooth NFT is optional Coating back Optional, please contact us for possibilities -

Neoprene timing belts MXL, XL ... XXH - classic tooth shape

The classic trapezoidal timing belts are still used today because of their simple construction and wide range of standard lengths.

We like to share our thoughts with you

Finding the right timing belt transmission starts with understanding your issue. After all, there is an optimal configuration of timing belt and pulley for every application. By better understanding the intended use of the timing belt transmission, we can find the optimal solution for your issue within our endless range of timing belts and pulleys equipped with all possible machining.

Our experienced experts are ready to work alongside you.

Looking for technical support from our specialist?

Suppliers & Brands

Related Products

Positioning

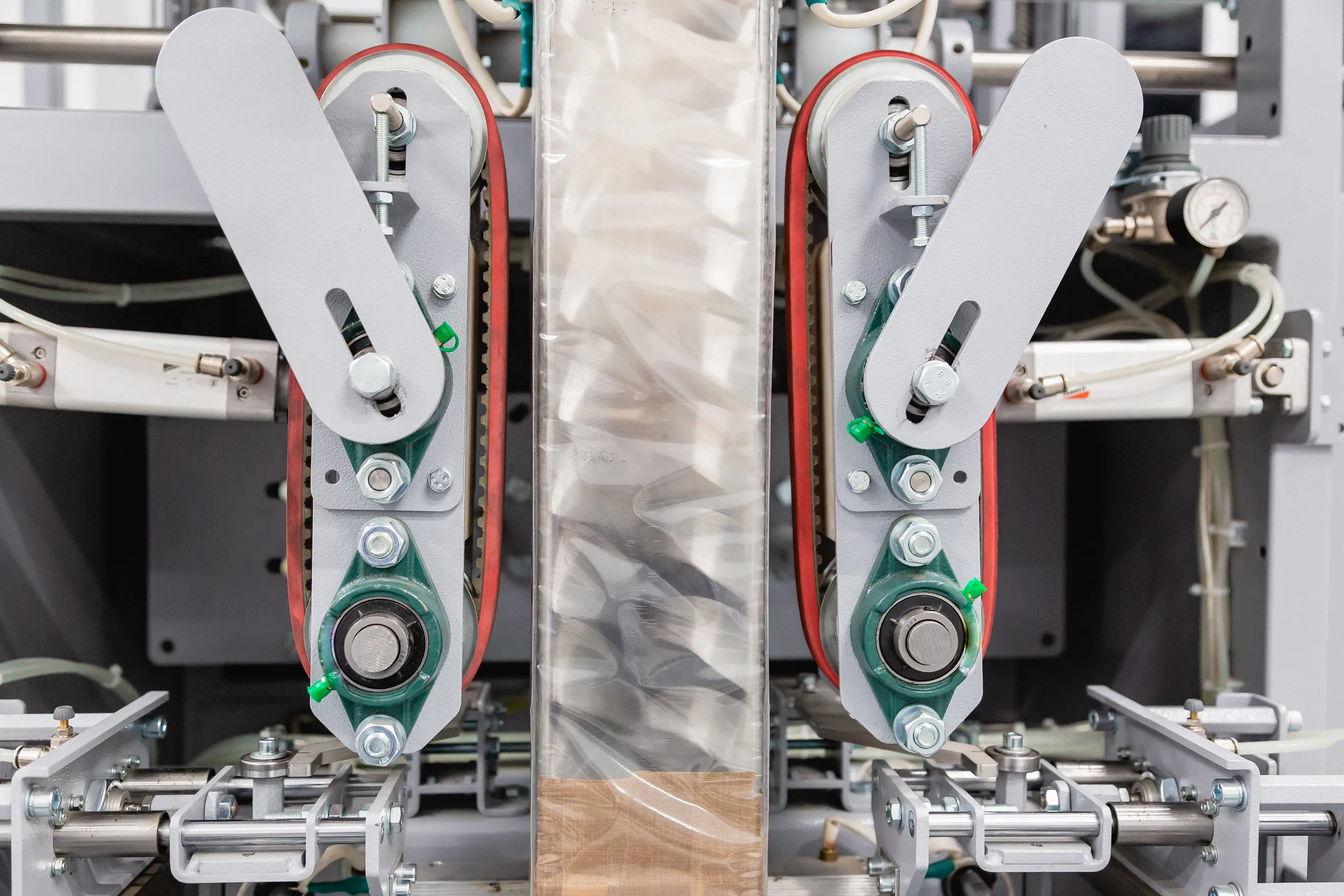

Conveying by timing belt

Vacuum belts

Special Timing Belt

Caldic Special Pulleys

easy drive Pulleys