Rexnord Premium Service

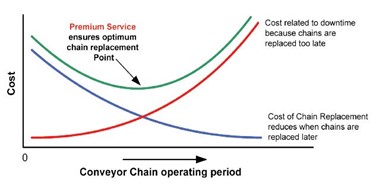

With the Rexnord Premium Service, we ensure that your conveyors stand still as little as possible by implementing a clear and efficient maintenance program.

Increase your productivity and reduce your maintenance costs

Plant survey

Caldic Techniek inventories for you the Rexnord components with the correct part codes and quantities per motor number (chains, belts, sprockets and curves). The inventory is thus carried out individually per conveyor.

Our conveyor specialists will visit you at a pre-arranged time and measure the conveyors, identify all components and map this out clearly. If desired, a customized advice on implementing standardization in your conveyors can be drawn up and a minimum stock recommendation can be issued.

Wear analysis

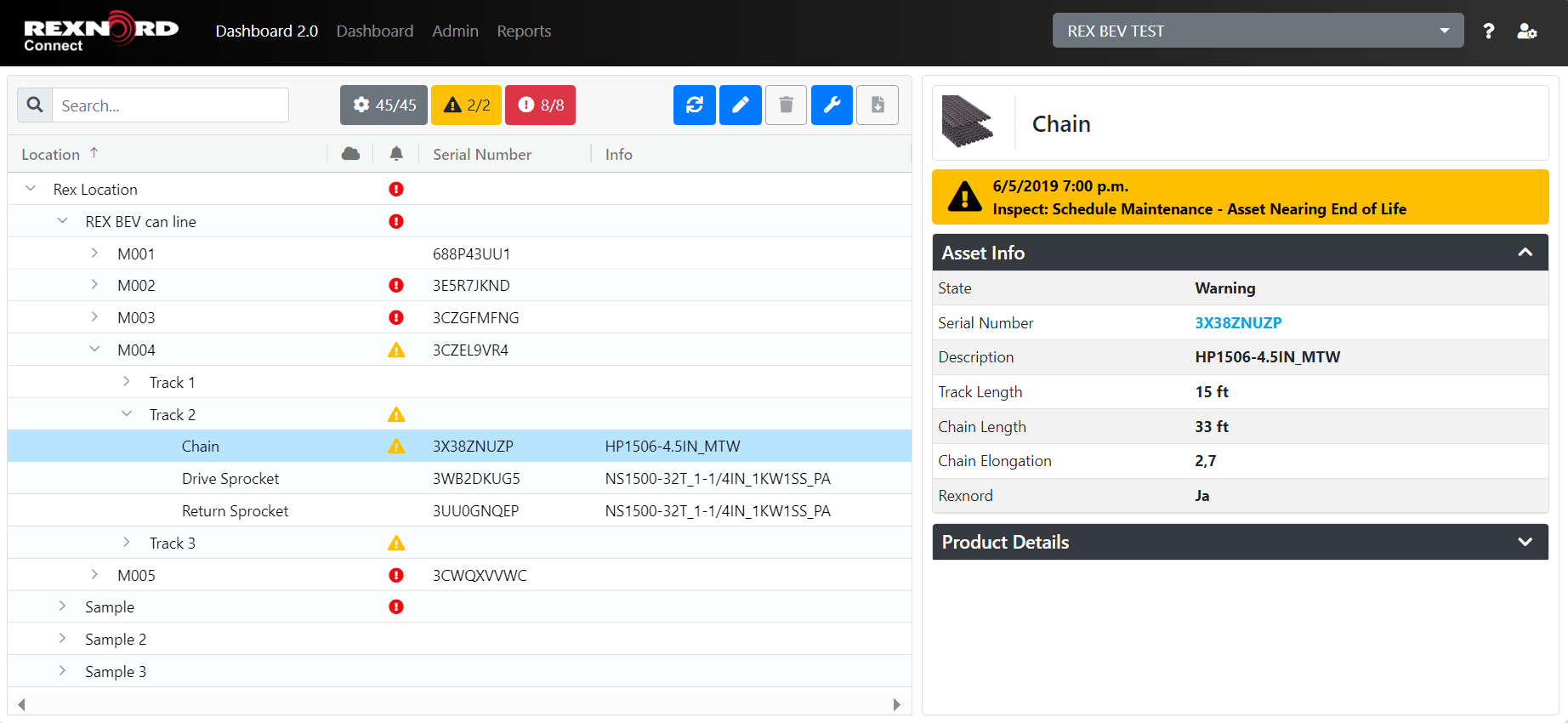

During the plant survey, the wear level of Rexnord components is recorded and recorded online in a secure environment. This gives you instant access to the right information at all times. You get a complete overview of the technical condition of your conveyors. In addition, the program provides an insight into future maintenance costs.

- Code green: Product is in good condition (no action required)

- Code orange: Product does not need to be replaced until the next overhaul (no action required)

- Code red: Product will not last until the next overhaul (replace)

QR code

Use your phone to scan the Rexnord QR code on the job and instantly know how much of which product is in the job. Your warehouse location can be added to this, so a technician does not have to search long for replacements.

Upon replacement, scanning qr code on the job and the QR code on the packaging of the new product ensures that the new product is updated with replacement dates in the Rexnord Premium Service

Report

The report is published online with associated replacement recommendations and can only be accessed by your authorized personnel. The report is built by line so that you have a good understanding of the status of each individual conveyor.

Benefits

- Standardization of chains.

- Reduced inventory costs.

- Stock recommendation for emergency repairs.

- Easy procurement of the correct product with the correct quantity.

- Optimal use of the tire/chain life through replacement advice.

- Historical cost overview per engine number.

- Future maintenance costs made transparent

Looking for technical support from our specialist?

Suppliers & Brands

Related Products

Conveyors

Conveyor Components

Conveying and Bottle Chains

Modular belts